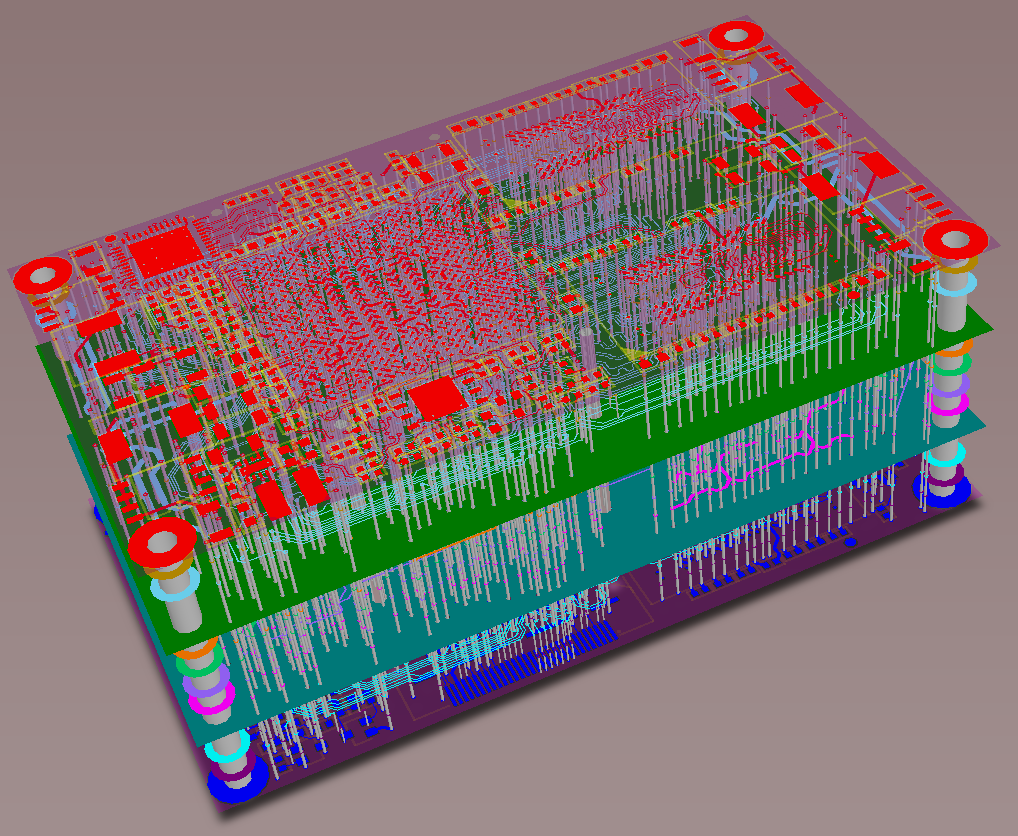

The core of any electrical gadget is a printed circuit board. It offers an assembly on which different electronic parts can be connected. In this way, the design and manufacturing process of PCBs depends on multiple layers. We will discuss the importance of the assembly layer, its components, and how they affect the general dependability and functioning of electrical devices in this article.

The Assembly Layer: A Blueprint for Manufacturing

As a guide for the production procedure, the layer of assembly gives precise details on the position and orientation of each electrical item on the PCB. For assembly workers, it acts as a visual guide to make sure that parts are connected and positioned correctly to form a working electrical circuit.

Orientation and Rotation

In addition to placement, the assembly layer provides information about the orientation and rotation of components. Proper orientation is crucial for ensuring that components are correctly aligned with the circuit design. The assembly layer specifies the angle of rotation for each component, preventing assembly errors that could lead to malfunction or failure of the electronic device.

Identifying Reference Designators

It includes reference designators alongside each component symbol, facilitating easy identification during the assembly process. This coding system streamlines the assembly workflow, reducing the likelihood of errors and ensuring efficient troubleshooting if needed.

Assembly Notes and Instructions

To further guide the assembly process, the assembly layer may include notes and instructions for technicians. These notes provide additional information that may not be evident from the component symbols alone. Instructions could include specific soldering techniques, component-specific requirements, or other critical details essential for the successful assembly of the PCB.

Challenges and Considerations in Assembly Layer Design

While the assembly layer is a critical component in PCB design, there are challenges and considerations that designers must address to ensure its effectiveness.

Complexity of Designs

High-density boards with numerous components pose challenges in creating a clear and concise assembly layer. Designers must carefully organize and present information to avoid confusion during the assembly process.

Miniaturization

The trend toward miniaturization in electronics presents another challenge in assembly layer design. Smaller components and tighter spacing require meticulous attention to detail to ensure accurate placement and soldering. Designers must strike a balance between compact designs and the clarity of assembly documentation.

Iterative Design Changes

Designers must update the assembly layer accordingly to reflect these changes accurately. Effective communication between design teams is crucial to ensure that the assembly documentation remains aligned with the evolving circuit design.

Pick-and-Place Machines

These automated devices are capable of picking up electrical components and placing them on the PCB in the proper locations quickly and precisely. The assembly layer guides these machines by providing the necessary coordinates, orientation, and reference designators for each component.

Surface Mount Technology

Surface Mount Technology is a famous and familiar assembly method where components are mounted directly onto the surface of the PCB instead of through holes. Because SMT parts are small, precise assembly documentation is crucial to preventing placement mistakes.

Conclusion

Architects have to overcome obstacles including design intricacy, downsizing, and iterative modifications to provide assembly documentation that is comprehensible, flexible, and clear. Moreover, advancements in assembly technologies, such as pick-and-place machines and SMT, underscore the dynamic nature of the assembly layer in accommodating and leveraging cutting-edge manufacturing processes.

If you want to know how much does PCB assembly cost? There are different factors, such as the complexity of the circuit design, the kind and amount of components, the assembly technique employed, and the degree of automation involved, on which the cost of PCB assembly.

In the end, the assembly layer is crucial to the production of electronic devices throughout their whole lifespan, from original design and manufacture to testing, quality control, and possible troubleshooting. Its precision and clarity enhance not only the effectiveness of the assembly procedure but also the general dependability and capabilities of the electronic devices that have become indispensable in our day-to-day existence.